TECHNICAL PRINCIPLE:

Optical Coherence Tomography (OCT) is a low-loss, high-resolution, and non-invasive medical and imaging technology developed in the early 1990s. Its principle is similar to ultrasonic imaging, except it uses light instead of sound.

Using a broadband wavelength light source and spectrometer, the device can capture images and analyze them by interference spectrum according to the wavelength of light. OCT can provide the surface profile and the underground structure and uniformity so that it can provide accurate information in real-time for diagnosis, monitoring, and process feedback.

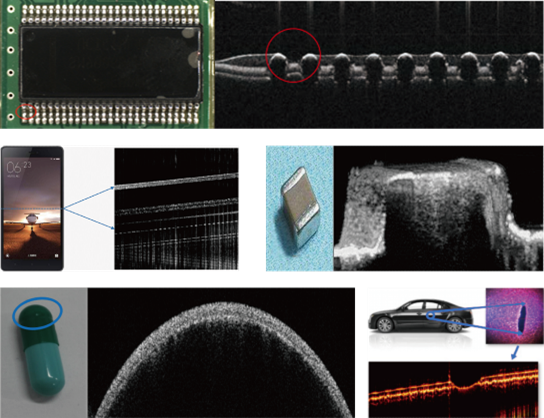

SCOPE OF APPLICATION:

• Thickness, defect, and damage detection of the internal structure of transparent or translucent film

• Such as conformal coating in the electrical industry, 3D screens of mobile phones, transparent resin coating, flexible OLED, and many other industries.

MAIN FEATURES:

• In-time-can deal with defective products in the production line in time.

• High efficiency-seconds level detection speed

• Non-destructive-non-contact, no risk to destroy the sample

• High accuracy-micron imaging accuracy

• Automation-can replace manual detection and reduce operating costs.

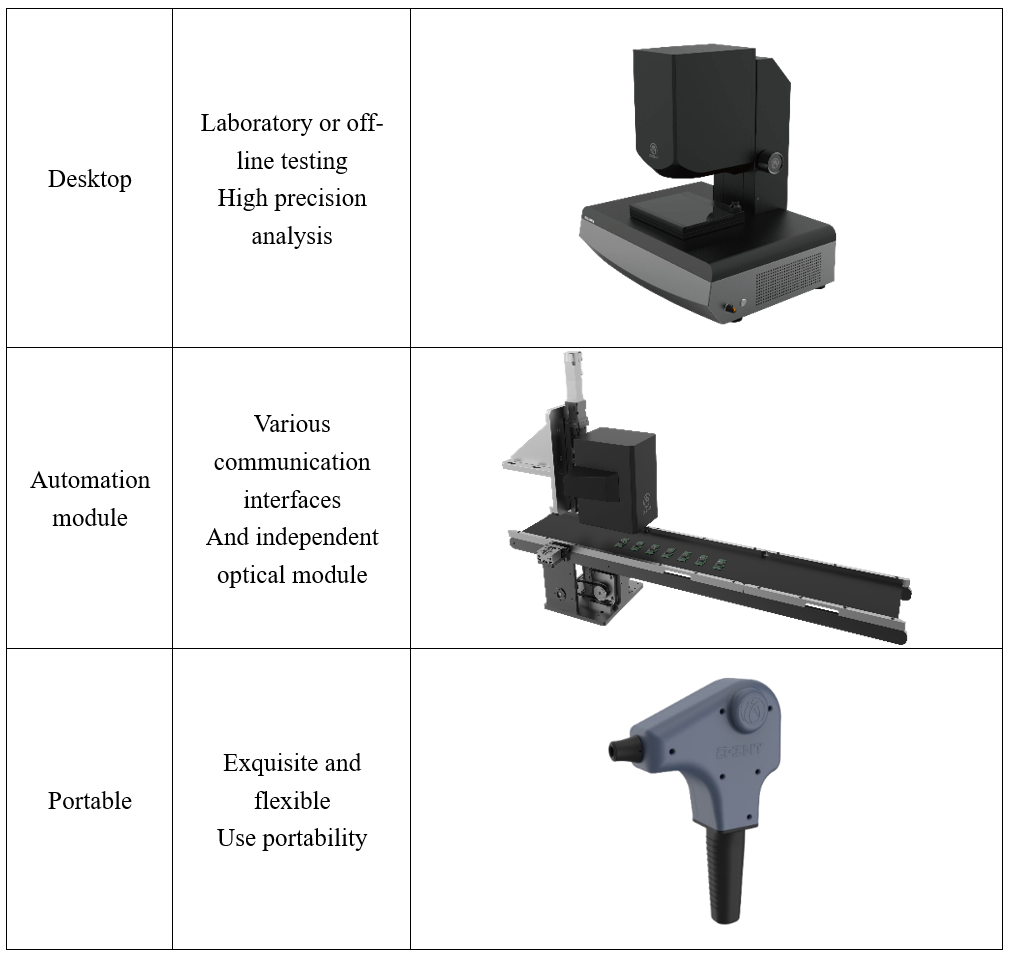

CORE EQUIPMENT (CUSTOMIZABLE)

EQUIPMENT PARAMETER LIST:

APPLICATION FIELD:

CASE STUDIES

1. Conformal Coating:

The 20~300μm film on the circuit board protects the circuit board from environmental erosion which leads to circuit board failure.

Typical quality problems:

Uneven thickness;

Bubbles and stratification;

Uneven curing.

In-time, online, nondestructive, and fast detection-industry blank

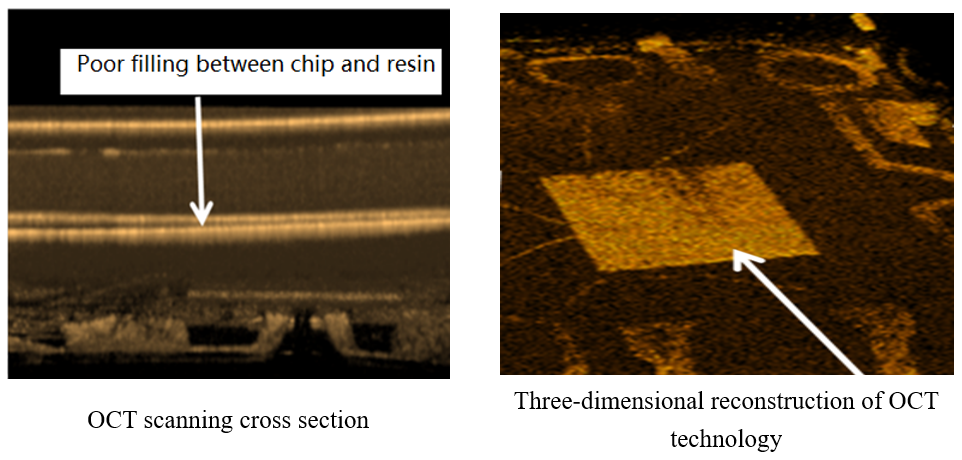

2. Comparison between OCT technique and metallographic analysis

In chip packaging, the problem of poor filling of Resin may often occur, and its resin or ceramic filling material can be penetrated by OCT technology for optical detection.

OCT scanning cross section Three-dimensional reconstruction of OCT technology

|